EBSD Explained

Techniques

Applications

Hints and Tips

Technology

OXFORD INSTRUMENTS EBSD PRODUCTS

CMOS Detector RangeAZtecHKL Acquisition SoftwareAZtecCrystal Processing Software

The detector is the single most important (and valuable) component of any Electron Backscatter Diffraction (EBSD) system. A good detector will enable the user to collect high quality diffraction patterns which, in turn, will result in better quality data, or alternatively may enable faster pattern collection and thus enable effective materials characterisation in a shorter time.

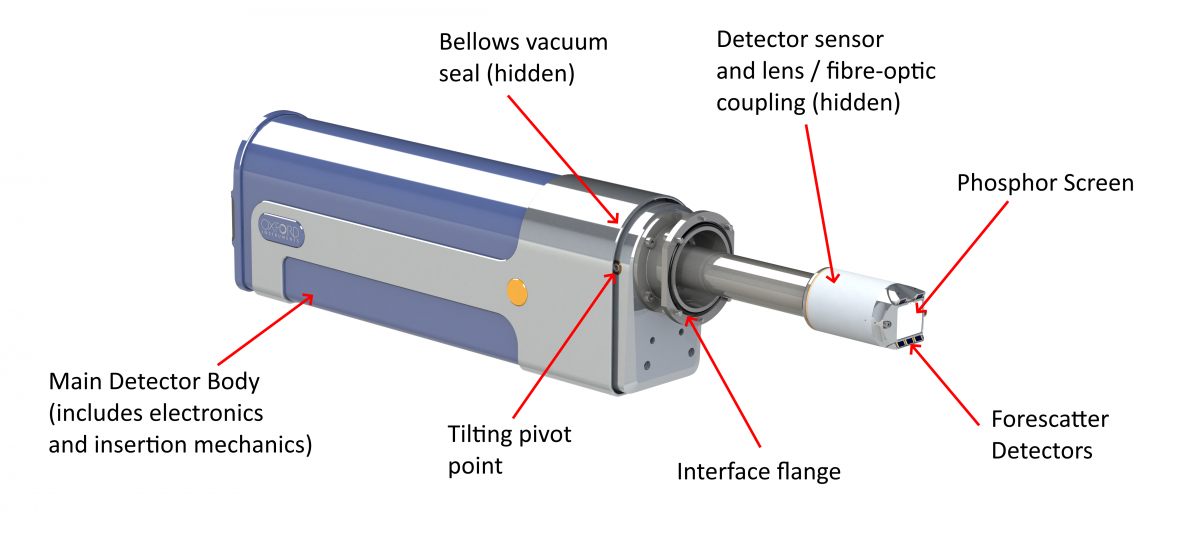

A typical, high-performance EBSD detector showing the major components

The function of an EBSD detector is essentially very simple: to capture, as efficiently as possible, the electrons that contain the diffracted information from the sample. The subsequent image is then passed over to the processing computer for enhancement and analysis. However, in reality there are many different parameters that define the performance of an EBSD detector. The detector requirements will vary according to the application for which it is being used – for example, a detector that will be used for high resolution (HR) EBSD measurements to determine elastic strain will likely require a high resolution (i.e. a large number of pixels) and minimal distortion, whereas a detector that is used for rapid characterisation of simple metal samples will benefit from a combination of speed and sensitivity.

The table below shows the main performance metrics of an EBSD detector. The ideal “all in one” EBSD detector will satisfy all of these, but some EBSD detectors are designed with a specific purpose in mind and may be less suited to other applications.

| Metric | Description | Importance |

| Maximum Resolution | The size, in pixels, of the highest resolution image | High resolution EBSD patterns are necessary for detecting very small shifts in the Kikuchi band positions, such as measured when performing HR-EBSD |

| Speed | The maximum speed of pattern collection and transfer (most detectors will have multiple speeds, dependent on the sensor mode / binning) | For routine characterisation, speed is of utmost importance (e.g. more samples can be analysed in the same time). Speed is also very important for in-situ experiments and 3D EBSD. |

| Sensitivity | Inversely related to the minimum electron dose required to achieve the experimental aim. Usually expressed in patterns per second per nanoamp (pps/nA) | Important for all EBSD measurements. Higher sensitivity will enable faster analyses with the same electron dose, or similar speed analyses with a lower electron dose. This measure of detector sensitivity is more useful than the Quantum Efficiency of the sensor itself, as it takes into account the whole detector system (phosphor, lens, sensor). |

| Binning | The grouping together of pixels to give lower resolution EBSD patterns | The concept of binning is not appropriate for all EBSD detector types. However, lower resolution patterns can usually be transferred and processed more rapidly although this can be at the expense of data quality |

| Bit Depth | The bit-depth of the EBSD pattern | A higher bit-depth will give more intensity levels in the image. Most EBSD detectors produce 12-bit images, but lower bit depths may enable faster analyses with minimal negative impact |

| Distortion | Distortion of the image relative to the ground truth, usually caused by lens imperfections | Distortion will negatively impact any high precision EBSD techniques, such as HR EBSD or refined accuracy indexing |

| Positioning | The insertion and elevation positioning of the detector | A higher precision of detector positioning will improve any auto-calibration routines. Elevation control (or detector tilting) provides significantly greater flexibility in the sample size and shape that can effectively be measured. |

| Safety | Collision prevention or warning system | Ideally this should be a mechanism to prevent collisions before they happen – e.g. to auto-retract the detector when coming into close proximity with another object in the SEM chamber. |

In the tabs below you can explore some of the historical developments of EBSD detectors and learn about some of the detector types commonly used for EBSD.

Early EBSD systems used relatively rudimentary low light TV cameras to capture the EBSD patterns. The pattern quality was generally poor but was sufficient for the semi-manual indexing approaches of the time. For applications that required high quality diffraction patterns, photographic film was used but obviously this approach was limited to single diffraction patterns at a time.

In the 1990s commercial EBSD detectors typically used charge coupled device (CCD) detectors or silicon intensified target (SIT) detectors. Speeds were usually limited to TV rates (25 or 33 Hz), although automated EBSP processing and indexing routines were generally the speed limiting factor. Slow scan CCD detectors were sometimes used for applications that demanded the highest quality EBSPs, such as for phase identification. Indeed, Goehner and Michael (J. Res. Natl. Inst. Stand. Technol. 101, 301 (1996)) demonstrated the use of a cooled, high resolution CCD detector, with a YAG scintillator and fibre-optic coupling, to collect excellent quality EBSD patterns for phase identification purposes.

Most commercial detectors at the time used standard phosphor screens and conventional lens systems, with EBSPs digitised to ~512 x 512 pixels.

Fully digital CCD detectors became the norm in the early 2000s: these were particularly suitable for EBSD because they offered an ideal balance of the key properties: good pixel resolution (e.g. > 1 Megapixel), high speed (using pixel binning) and high dynamic range. All commercial detectors at this stage were using standard phosphor screens and lens systems, and were capable of speeds up to ~100 patterns per second (pps).

In about 2003-2004, the first higher speed CCD detectors were developed: these usually had a lower maximum pattern resolution (e.g. 640x480 pixels) but had dual read out, enabling significantly increased analysis speeds but with a lower sensitivity. With a continued push towards greater pixel binning, such detectors were capable of speeds of >1500 pps by 2015.

Graph showing the increase in EBSD analysis speeds since the first commercial systems were developed in the early 1990s. Note the logarithmic speed scale.

In 2017 the first commercial detector using a complementary metal oxide semiconductor (CMOS) sensor was released. Unlike CCD sensors, CMOS sensors have a more parallel architecture and can read out higher resolution images at high speeds. This resulted in a significant jump in analysis speeds to >3000 pps, with improved pattern resolution.

Recent years have seen a continued development in CMOS detector technology, and the first forays into the use of direct electron detectors for EBSD.

The chart above shows how the analysis speeds of EBSD detectors have improved since the first commercial EBSD systems were developed at the start of the 1990s.

There are currently 3 main EBSD detector types available commercially: 2 types of “indirect electron detector” that use either a charge coupled device (CCD) or a complementary metal oxide semiconductor (CMOS) sensor, plus direct electron detectors.

An indirect electron detector is one in which the electrons that impinge onto the detector screen are converted into light (i.e. using a scintillator), and that light is focused onto an imaging sensor (either CCD or CMOS). The light is converted back to electrons on the sensor and the resulting image is digitised and transferred to a computer for subsequent processing and analysis.

Until recently, most indirect electron detectors utilised CCD sensors. CCD technology is essentially a serial technology: the signal is funnelled through a single charge-to-voltage output node and then converted from an analogue to a digital signal off-sensor. These bottlenecks limit the readout speed from the sensor so, in order to achieve fast imaging rates, pixel binning is required.

Pixel binning involves the grouping of an array of pixels (e.g. 2x2, 4x4 etc.) into a superpixel. The signal from the superpixels can then be read off the sensor more quickly, but at the expense of a loss of resolution and a drop in the dynamic range. The following image shows typical EBSPs at different binning levels. The most heavily binned patterns, with a final resolution of 40 x 30 pixels, are still sufficient for reliable indexing if the initial EBSP quality was good, but are not suitable for more challenging materials (e.g. samples with complex phases or significant deformation).

Images showing the effect of binning on EBSP quality and resolution using CCD-based detectors. Left – full resolution EBSP (high sensitivity detector). Centre – 8x8 binned EBSP (high sensitivity detector). Right – 16x16 binned EBSP (lower resolution, fast detector). The electron dose decreased with increasing binning (to avoid oversaturation). Note the trade-off between pattern quality and speed.

CMOS sensors have a more parallel architecture than CCD sensors: charge to voltage conversion occurs within each pixel and whole rows of pixels are addressed simultaneously for analogue to digital conversion. This means that no pixel binning is necessary: high signal to noise ratio and high resolution are retained even at the highest speeds.

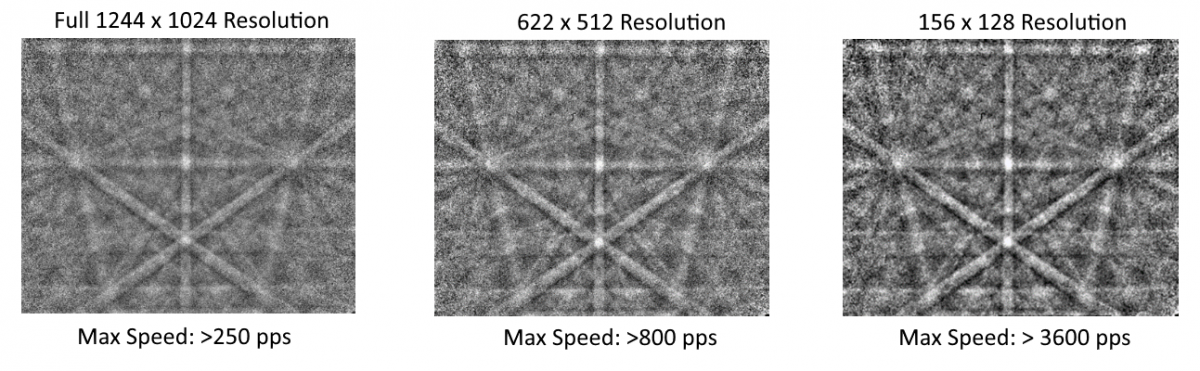

However, for EBSD we generally do not need full megapixel resolution patterns – these take longer to transfer, longer to process (e.g. for background correction) and longer to index. Therefore, even though a CMOS sensor can image at high speeds and high resolutions, it is still desirable to reduce the resolution in order to speed up the rest of the EBSD processing workflow. However, unlike with CCD-based EBSD detectors, there is no significant loss of dynamic range and very high speed analyses can be carried out using relatively high quality EBSPs (e.g. 156 x 128 pixels). This is demonstrated in the following image, which shows EBSPs collected from a Si single crystal using a CMOS-based EBSD detector using the same electron dose but at different resolutions.

Images showing the effect of changing EBSP resolution using CMOS-based detectors. Left – full resolution EBSP. Centre – EBSP with resolution reduced by a factor of 2x2. Right –EBSP with the resolution reduced by a factor of 8x8. All patterns were collected using the same electron dose. Note how the pattern quality is maintained across all resolutions (and speeds).

The comparison between the high speed EBSPs collected using a CCD and a CMOS sensor demonstrates how a CMOS-based EBSD detector can acquire extremely high speed data without compromising on data quality. The latest high speed CMOS-based EBSD detectors can acquire data at close to 5000 indexed patterns per second.

A direct electron detector (DeD), as the name suggests, detects electrons directly without any intermediate step (such as converting the electrons to light using a scintillator). Direct electron detectors have been used successfully in a range of scientific techniques, most notably in the field of transmission electron microscopy (TEM). This is not surprising: one of the most significant benefits of direct electron detection is the ability to detect single electron events. In many TEM analyses, especially in the field of electron crystallography, the ability to image while minimising the electron dose (and therefore damage to the sample) is a significant advantage of DeDs over conventional detector systems.

For EBSD the challenges are quite different: there is no benefit to working with extremely small electron doses, so the system noise (the noise caused by the electronics of the sensor) is rarely an issue. In other words, there is little benefit to working under conditions where the detection of single electron events is an advantage. Indeed, under usual operating conditions, an optimised indirect electron detector will have a superior sensitivity to a simple electron counting DeD operating with a low energy threshold. This is described in detail here. This surprising result, coupled with the general higher cost of DeDs, helps to explain why the EBSD market, despite the availability of commercial DeDs, has been slow to take up direct electron detection technology (plus the fact that, at present, no DeD can be considered a suitable detector for a wide range of EBSD applications).

However, DeDs have the potential to offer many benefits for EBSD. Assuming an appropriate energy threshold is selected (to exclude the large number of lower energy electrons that contain no useful diffraction information), then a DeD should be able to operate with a better sensitivity than an indirect electron detector, especially at lower beam energies where the phosphor efficiency decreases. In addition, the complete lack of distortion and the potential for flexible sample-detector geometries may prove beneficial for certain EBSD applications.